SUSTAINABILITY

CORRUGATED AND ENVIRONMENT

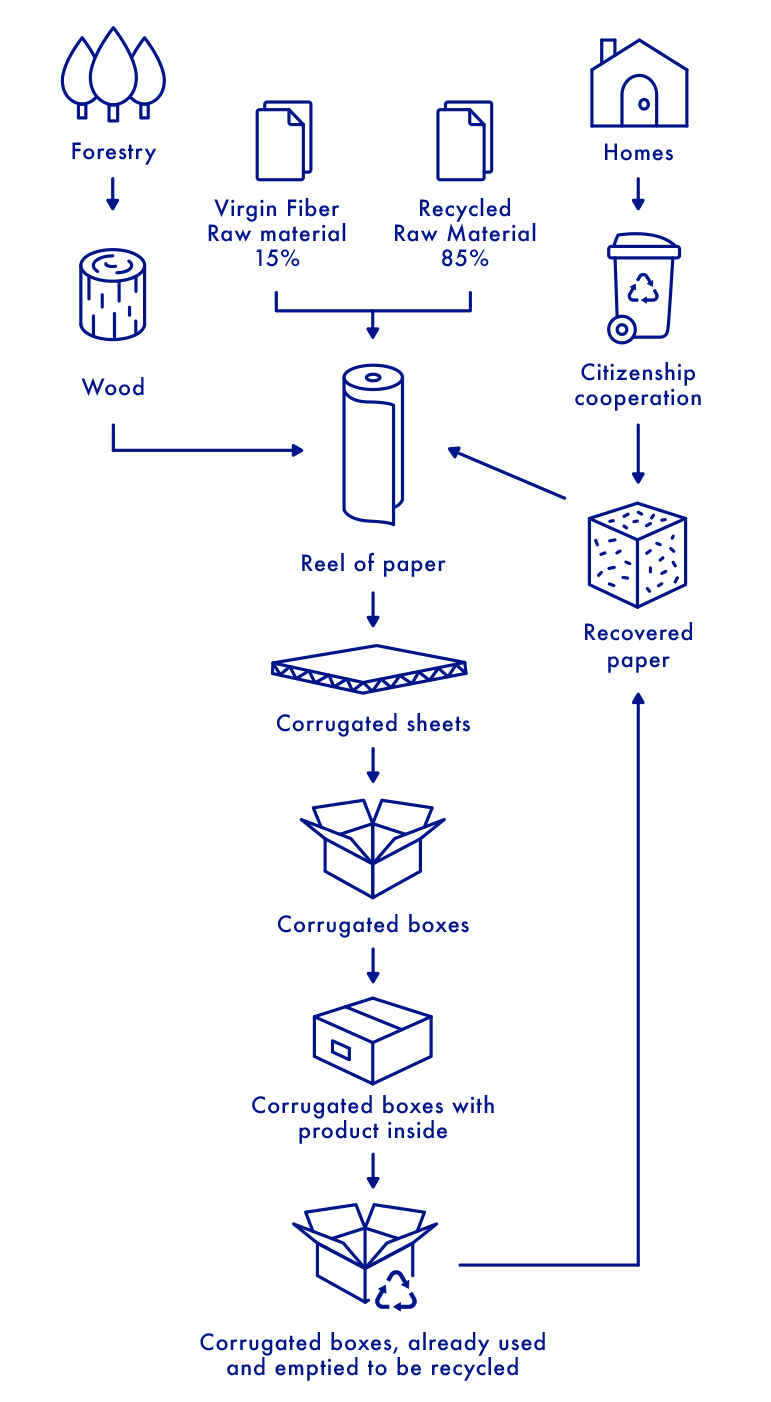

Corrugated board is made from layers of paper. Paper used in corrugated manufacture can be made from cellulose (virgin) fibre obtained from wood, or it can be made from recovered material from recycled paper and packaging products.

As a naturally renewable resource, the wood pulp used in the manufacture of corrugated material comes exclusively from controlled forestry. The introduction of controlled forestry has resulted in a 10% growth of European forest.

Corrugated, a leading material in containers and packaging, is recyclable and biodegradable. Thanks to recycling, a used box becomes raw material within weeks of its original manufacture, creating a huge benefit for the environment as renewable resource. The corrugated packaging industry is responsible for CO2 emissions equating to less than half the emissions generated by all other packaging industries put together.

The Alliabox group is aware of its responsibility towards our planet. Be it use of recycled paper or controlled use or virgin fibre, our partners encourage and support sustainable manufacture and development.

The Plastic Debate: Facts

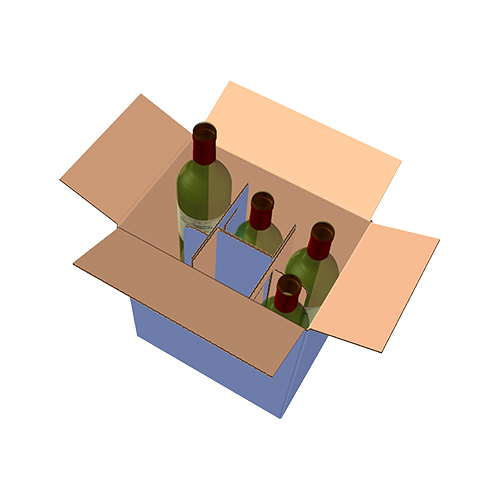

Being tailor-made, containers and packaging made from corrugated materials, are space-wise; saving every millimeter on pallet, in warehouses and on trucks. They do not carry air and are fit for purpose at every stage of design.

Comparing single-use biodegradable containers with non-biodegradable re-usable containers, corrugated is always the best option. The use of corrugated packaging reduces the number of vehicles on the road, reducing costs and lowering overall environmental impact.

Corrugated packaging offers the highest level of hygiene across any supply chain. Used only once, as a single trip transport medium, paper based packaging demands nothing from harsh, polluting chemical cleaning.

Our long-term vision of the future is one of sustainability and environmental stewardship, led by every one of our members in a united stance of continual responsibility.

corrugated cardboard cycle